High Speed Trademark Machine: Driving Efficiency and Precision in Branding

Jul 28, 2024|

Jul 28, 2024| View:43

View:43High Speed Trademark Machine: Driving Efficiency and Precision in Branding

I. Definition of High Speed Trademark Machine

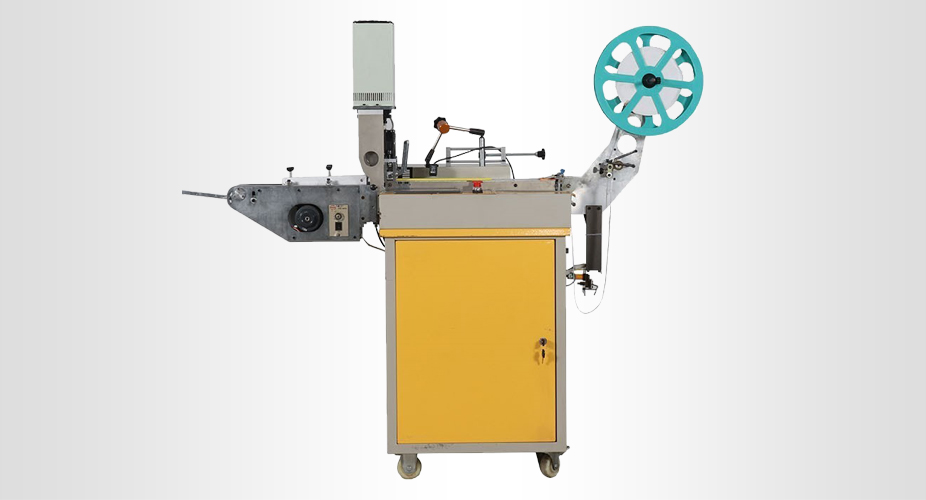

HS Trademark Machine is a special equipment for ultra-speed and precise trademark production. Using advanced technologies and complex mechanisms, it produces state-of-the-art trademarks that are used in a huge number of products and applications.

In most numbering machines, you will find the following basic units: a feeder that provides raw materials; printing or marking systems for displaying the design of section of machine pressed on an item; cutting tools to fit them in specific sizes and shapes according to job work requirements.; control system that scans all over operation. The feeding system delivers labels, tags or fabric continuously and smoothly. Such a characteristic trademark may be generated or fabricated by the printing or marking units through, for example, inkjet-printing-laser solution technology in association with laser engraving and/or embossing. The trademark is cut or shaped to the required sizes by mechanical cutting devices. A control system configured in operators to manage aspects as printing resolution, speed and design complexity for specific requirements.

II. Benefits of High Speed Trademark Machine

Increased Production Output

The most important function of the High Speed Trademark Machine is to quickly produce a large number of trademarks. For businesses that run high-demand orders or a tight production schedule, this is definitely necessary. Take the example of apparel industry, where branding for tons of clothing items and with high-speed enables timely delivery.

Status: Higher quality and more consistent

These machines are designed for making precise and consistent marks on all surfaces so that every marked product is unflinching with whatever comes of quality standards. Keeping the brand consistent increases consumer awareness and shapes their view of who you are as a company. A clearly-delineated and consistently-used trademark for a product line also suggests professionalism.

Customization Options

High Speed Trademark Machines is highly customizable. These are useful for distinct patterns, colors and material that can cater to businesses in creating distinctive individualized trademarks above all other trademarks. And importantly, for brands wanting to stand out from the competition.

Cost-Effective Production

They help save costs in the long term by reducing production time and limiting material wastage. This more efficient use of resource (and hence, higher productivity) also results in lower per-unit production costs - that is to say an even cheaper branding process.

High-tech Specifications

A lot of high-speed trademark machines are followed up with these functions: automatic error detection, real-time monitoring and remote control etc. These features help to improve operations whilst reducing the risk of error and easing management and troubleshooting efforts.

III. Applications of High Speed Trademark Machine

Apparel and Textile Industry

For labeling of clothing, shoes and accessories. This machine is able to perform cuts on many kinds of fabric and material, leaving a clear, robust mark.

Things related to electronics and electrical

Series production of electronic devices, cables and components For the marking on appliances (brand name), type plates AENOR operation or construction registration number Manufacturing certificates This high precision makes it both readable and conforms to industry standards.

Packaging Industry

Used for making labels and packaging decoration to improve product aesthetic appearance & brand identity. This also helps in drawing the attention of consumers towards buying and specifying a desirable product.

Automotive Industry

Responsible for branding Automotive Parts & Interior + Exterior Badges. The logos need to be durable enough and survive in harsh conditions.

Personal Care and Cosmetics

Staining of contaminants, cosmetics and personal care products such as brand labels or product details on the container bottle packaging.

IV. Common Issues of High Speed Trademark Machine

Maintenance and Calibration

As with any machinery, the grinder needs to be properly maintained in order for it to keep functioning well. Parts such as print-heads, cutting tools and sensors may also need to be cleaned or lubricated and calibrated so they can function precisely. Without good maintenance, people could get less or have more equipment downtime.

Compatibility with Inks and Materials

Ultimately, using the wrong ink or incompatible materials can lead to bad printing and holding badly on a machine. It is also very essential to adhere to the guidelines of printer manufacturing company who have specified for ink and material.

Software and Firmware Updates

The performance and functioning of the machine is limited to outdated software or firmware. JRPG is just one of a few features added from new software to firmware updates on the homebrew device, and could easily be swept away by it's users without staying current.

Operator Error

Misuse or non-compliance with safety procedures can lead to machine malfunctions, production defects and even security risks. Avoid these types of problems by providing more comprehensive operator training.

Power and Electrical Concerns

An unstable power supply or any kind of electrical fault can disturb the functioning of a machine. Though installing the effective power conditioning equipment and thereby ensuring a sychronized electrical connection could ascertain smooth operation.